The idea

Even as a child, there was great interest in gliding. At the age of 10 I built the first glider models and spent many hours on the nearby airfield. I particularly liked an old, double-seated Ka4 Rhönlerche. The idea of having a plane like this came, after I had the opportunity to accompany a flight in the passenger seat.

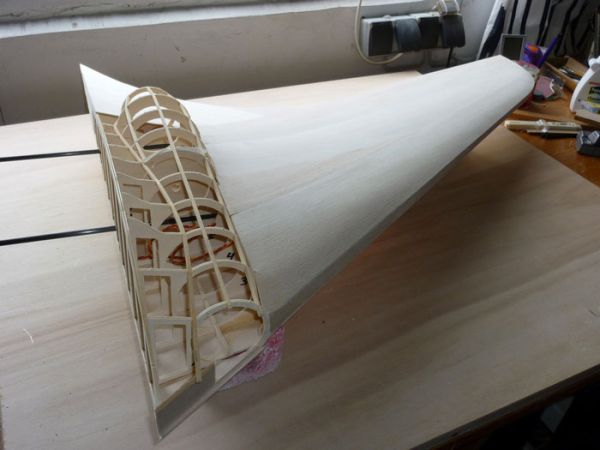

It was almost fifty years later. It wasn't a man-carrying glider, but it was a very large model

The project

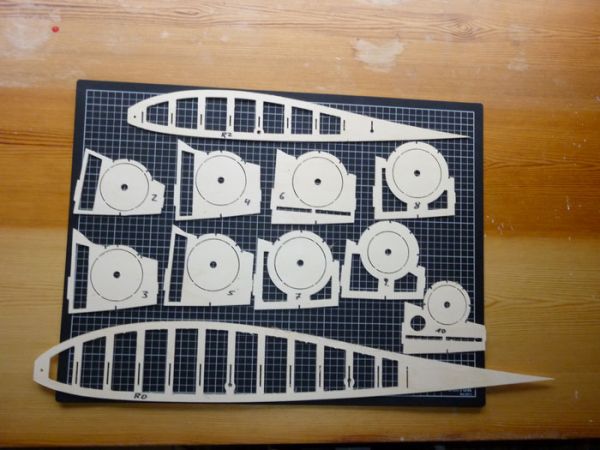

This was possible because the designing engineers of the glider model (Gudrun and Holger Baars) had set up a small business at the beginning of 2010 for production of milled parts sets and wooden construction kits for glider models – CNC-Bauteile.eu.

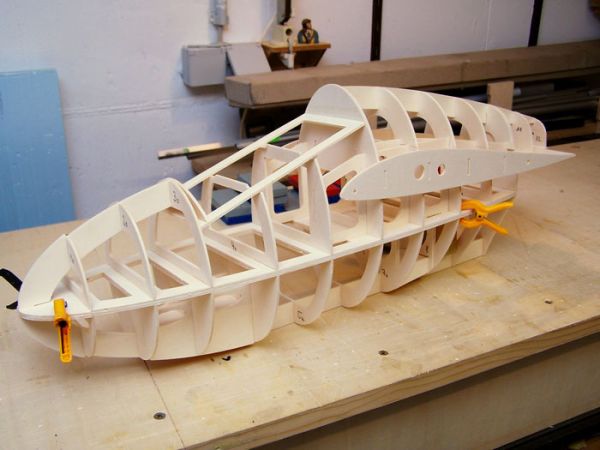

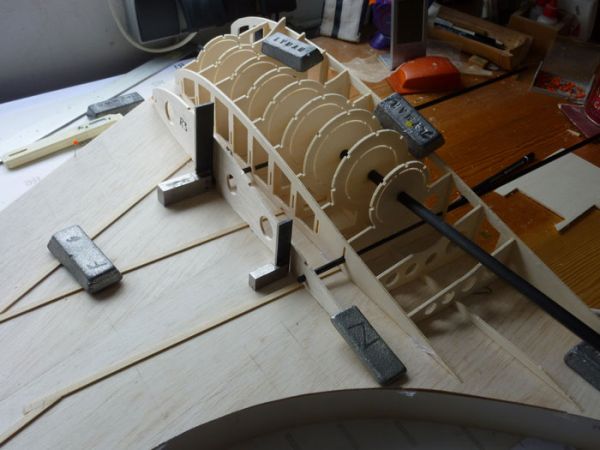

The project to build the Rhönlerche with a span of 6 meters started in May 2015 and took two years to get the prototype flying. The first flight on May 25th, 2017 in Burgau was very successful.

Our wood supplier in Germany, Thoma Balsaholz GbR, ensures first-class wood for the production of the milled parts. 45 years of experience in the sale of wood to end customers ensure selected and consistently good quality. Thoma Balsaholz GbR obtains its material from Italy from the company Panguaneta Plywood.

Why to use poplar plywood

Gliders have to be very stable and light at the same time. The wings in particular are heavily loaded during the flight. Since the 1960s, therefore, more and more modern synthetic fibers are used such as GRP, coal or for example carbon. The concept of CNC-Bauteile.eu is, however, to recreate only the old wooden gliders.

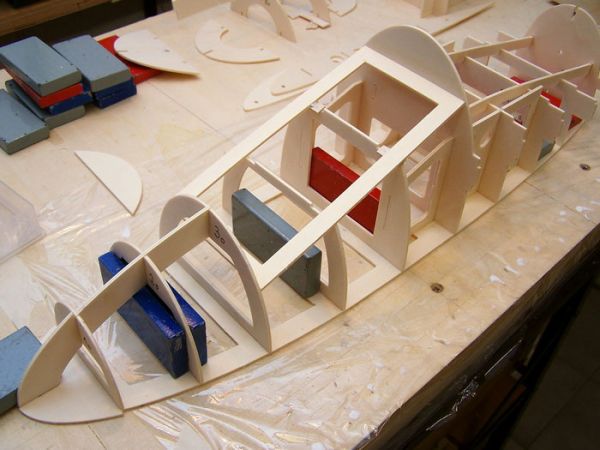

It is all the more important to pay attention to stability, low weight and easy processing. Poplar plywood is the ideal material for this. While balsa was previously used as solid wood for almost everything, nowadays these parts can be almost completely replaced by poplar plywood with an almost comparable weight. The use of CNC technology makes it possible to mill cut-outs precisely and statically correct in every piece of wood.

Therefore our milled parts for the old glider models consist with an average of 80% of poplar plywood.

Flight characteristics and flight duration

Good flight characteristics cannot be directly derived from the use of poplar plywood. Good flight characteristics result from a low and balanced weight of the model - and the use of poplar plywood contributes significantly to this!

The Rhönlerche flies very leisurely and is easy to control. Their flight characteristics are even significantly better than the original. On the second flight, the pilot was able to sail in the air for more than 50 minutes - there is no engine!

The weight of the ready built 6-meter model was around 17 kg, which is very light for this size of a model with a huge fuselage and deep wings - thanks to Panguaneta plywood!

Thoma Balsa GbR: https://thomabalsa.com/

CNC-Bauteile.eu: https://www.cnc-bauteile.eu/

!["Meet the Champions 2024": Panguaneta joins the tour […]](/images/news/impresachampion24.webp)

![Panguaneta takes part to the event “convention Fibopan […]](/images/news/fibopan.webp)

![Panguaneta participates in Palm Academy event on sustainable […]](/images/news/2024-03-08.jpg)

![The business association “Il Circolo delle Imprese” stops […]](/images/news/2024-01-26.webp)

![Nicoletta Azzi, CEO Panguaneta, meets the Minister Pichetto […]](/images/news/2024-01-16.webp)